Paper Publication|A Review of Metal-to-Plastic Joinery in Automotive Manufacturing

This post will introduce the paper I participated in the research project about the joining of plastic and metal parts in the automotive industry.I studied more than 100 related documents, and formed a group led by the first author and corresponding author.

Papers displayed on this website have been published in relevant journals/conferences and are protected by copyright. Unauthorized copying, reprinting or plagiarism in any form is prohibited, which will constitute a violation of intellectual property rights. Please respect the rights and interests of authors and abide by academic ethics, otherwise legal responsibility will be pursued.

本网站展示的论文已经在相关期刊/会议上发表,并受到版权保护。未经授权,禁止复制、转载或以任何形式进行抄袭行为,这将构成知识产权的侵犯。请尊重作者权益,遵守学术道德,否则将追究法律责任。

It has now been accepted by International Conference on Mechatronics and Smart Systems. It will be published inJournal of Physics: Conference Series (JPCS) (Print ISSN 1742-6588) or Applied and Computational Engineering(ACE) (Print ISSN 2755-2721).They will be submitted to EI Compendex, Scopus, Conference Proceedings CitationIndex (CPCI), Crossref, Portico, Engineering Village (Inspec), Google Scholar, andotherdatabases for indexing.

Certificate of Acceptance

The following is the outline of the paper, please click the link to read the original text.

A Review of Metal-to-Plastic Joinery in Automotive Manufacturing

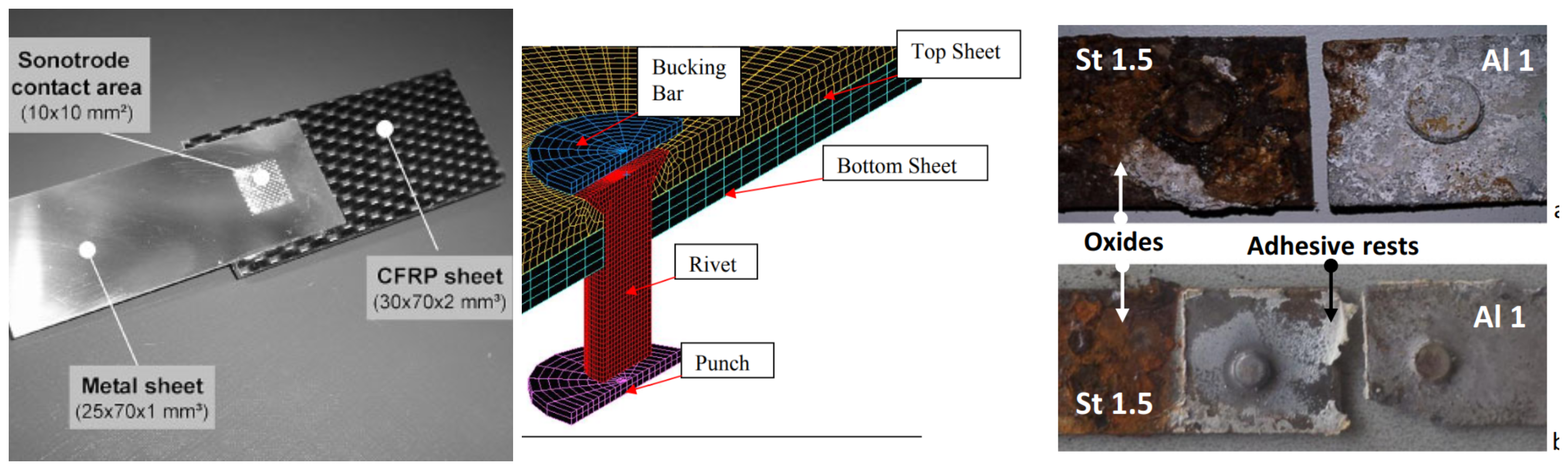

Abstract: Reducing weight and improving energy efficiency are key design goals in the automotive industry,In order to reduce the weight of the car body, engineers often use plastics in the parts of the car that require less strength. However, due to the difference in material properties, when using plastics to connect steel frames, there are disadvantages such as small interface area, large number of interfaces, and poor reliability of plastics, which may have a great impact on the safety of the car. Therefore, these plastic parts Joinery to the steel frame of the car needs careful consideration. Various methods, such as welding, bolt and nut connection, riveting, and crimping, were considered to connect plastic and metal in automobiles. This article first introduces the specific implementation of the joinery method between plastic and metal, and investigates their process difficulty, interface strength, vibration resistance and the least negligible cost. Discusses where these processes are suitable for use in the car, where they are currently used, and explores potential future developments.

Keywords: Welding, Crimping, Rivet, Bolts and Nuts